2018/12/19 10:00 | Pageview:2710 | From: eurekamagazine

The API Robot Measurement Solution (RMS) provides a single seamless solution for robot process performance enhancement and optimisation. RMS can be supplied as a Robot Performance Measurement module or combined Robot Calibration (RoboCal) and Robot Path Plan Enhancement (PPE) module. Robocal offers both DH kinematic model and a volumetric error compensation (VEC) model to update robot accuracy using collected data. Once a robot has been calibrated, existing robot path programs can be automatically updated driving the robot to its corrected calibrated positions.

Robot performance measurement is quantified by examination of an installed robot performance in accordance with the ISO 9283 Standard. Robot performance verification is the process of identifying the real geometric parameters present in the kinematic structure of a robot, such as relative positions of robot joint links. A total of 14 static and dynamic tests are used to quantify a robot's absolute performance. This performance check determines actual robot performance against the original OEM specifications, quickly determining robot accuracy, repeatability and identifying inherent robot joint wear.

Robots are historically repeatable but not accurate. Today many automation tasks require improved process control and a higher order of accuracy than that delivered by robot manufacturers. For instance, aerospace machining, drilling and assembly operations are increasingly performed by robots integrated into sophisticated and process critical manufacturing cells.

Typical applications for enhanced robot positional accuracy include machining, drilling, grinding, welding, cutting, inspection, deburring and 3D printing. Activities such as robot cell 'cloning', 'cell mirroring' or 'robot swapping' also benefit from enhanced robot accuracy by reducing manual programming time and allowing for seamless and precise off-line robot programming. Accurate robots improve process capability as a robot positions more accurately to its commanded position – also negating the physical 'touch-up' of robot programs.

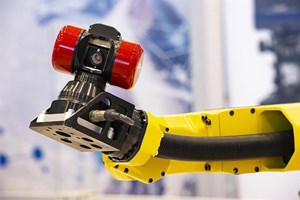

The delivered solution includes API's 6 DoF (Degrees of Freedom) RADIAN Laser Tracker complimented by the API Smart Track Sensor, which mounts directly to the robot's end effector, allowing the laser tracker to dynamically collect x, y, z, and i, j, k data for each robot position in space accurately and automatically.

API will exhibit their latest products and measuring technology at SIMM Exhibition on March, 28-31, 2019. This new evolved solution for robots accelerates the process of industrial measurement that we all expect RMS robot accuracy verification and solution can help our all manufacturers in manufacturing industry.

Loading...

Loading...