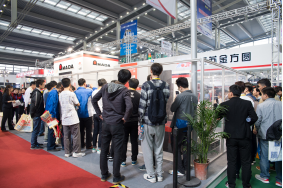

Benefitting from the increasing demands of metal works and fast development of manufacturing in South China, SIMM Sheet Metal and Punch Automation Area attracted many world-class sheet metal processing manufacturers such as AMADA, Han's Laser, SALVAGNINI, Yawei, JFY, Yangli, Yadon, Wanshun, CPTEK and many other famous companies to display their latest technology. SIMM has become one of the two largest sheet metal processing technology exhibitions in China.

SIMM 2019 will present with approximately more than 200 sheet metal, punching and automatic punching companies in metal forming industry. The items on display cover the whole sheet metal processing industry chain ranging in uncoiler, flattener, laser cutting and stamping, cutting, dadoing, surface treatment, detection and fastener. Whether you are a newly built small factory or a big company, SIMM is qualified to meet your demand of equipment purchase, process improvement and smart solutions.

SIMM 2019 will focus more on the display of high speed punching, servo presses, smart punching and sheet metal automatic technology to provide solutions for factories to realize intelligent manufacturing and smart factory.

Press machine:

servo presses, high speed punching machine, mechanical press, hydropress, oil press

Press automation:

pressing manipulator, press surrounding automation, punching production

Sheet metal automation:

automatic production line of sheet metal processing, bending robot and automatic feeding machine

Features and Trends of the Display:

Servo pressing technology can meet demand of smart punching with advantages of controlled slider speed, easy made nature of hard forming materials, energy efficiency and environmental protection, multiple function and intelligence, which are the mainstream of punshing industry. These advanced and core technology has been monopolized by overseas companies for a long time. CPTEK launched the servo pressing machine, filling up the blank in industry in China and won the orders of Shanghai Automotive Industry Cooperation (SAIC) and FOTILE. This year in SIMM, CPTEK displayed their featured product and new technology - 400T cold extruding press machine and presented the punching process operated by robot with molds and four-axis punching and received recognition.

Representative Exhibitors:

AMADA servo press, CPTEK, CHIN FONG, SHIEH YIH MACHINERY INDUSTRY

Features and Trends of the Display:

The high-speed precision press has advantages over the common press in obviously enhancing productivity, improving product quality and prolonging the mold life. In the context of technology and market being monopolized by foreign enterprises, SEFTEC high-speed precision press successfully grabbed the market share by the technology advantage in the precision and efficiency of the press, which is 3 times advanced than that of other domestic companies thus successfully replacing the overseas brands. Aiming at the strong market of 3C consumer electronics industry in South China, SEFTEC took part in SIMM exhibition for years and wins customers' trust.

Representative Exhibitors:

SEFTEC, Protrade, CHEN LI Machinery

Features and Trends of the Display:

Press automation is the industry trend, which not only solves the problem of labor, safety and work intensity, but also enhanced production efficiency and product quality to help the transformation of company production mode. SIMM 2019 stays closer to the practical demands of South China market, focusing on the application of press automation in areas of automobile, home appliances, electronics, communication, medical services, hardware accessories, new energy to match the exhibitors and key manufacturing enterprises in South China.

Representative Exhibitors:

Guangdong Metal Forming Machine Works CO. LTD, YADON, YANGLI, WORLD GROUP, HAIWEI, TONGCHUAN TECHNOLOGY, MAHATMA, AOMATE, GOANWIN, PAK TAT Machinery, Dongtai Group, MING JIANG, DAGONGXING, JINTUO, Kexin Machinery, XINTAIMING, TOMAC Machinery, Zhe Sheng, HENRY MACHINE TOOL

Features and Trends of the Display:

Sheet metal automatic processing is the inevitable choice of factories and the future development trend. The market made a quick response. Multiple sheet metal automatic processing units were displayed in SIMM and it was convenient for customers to obtain many successful cases and cost data analysis for purchase. This is a convincing exhibition mode.

Representative Exhibitors:

●Display of AMADA bi-servo CNC press EMMⅡ+MP2512-L automatic self-feeding system; High-precision automatic bending machine EG6013AR carried a multiple-purpose precision manipulator, which can realize 24 hour automatic processing of small items.

●Han's Laser: G3015 fiber laser cutting machine +ALU3015MS self-feeding system, robotic 3D soldering system. AWEA: F.SXH1225A single self-feeding system, automatic units of sheet metal which realizes self-feeding, shearing, sorting and other processing procedures.

●JFY: sheet metal MT single charge servo, the automatic production line of composite punching shear. ATM: self-feeding system which takes just 8 seconds to load materials reduces the labor intensity and improves the production efficiency. HPR bending machine + KUKA robot: good at positioning and repeating, qualified clamping effects and the bending function resists distortion.

●WORKMAN: CNC turren press + multiple automatic self-feeding system ensure the stability of the high-speed moving of sheet metal and enhance 30% the processing speed. Bending machine + ESTUN manipulator on-site display.

●YANGZHOU HENGA HB1031 bending machine+HR50 bending robot ensure safety, precision, self-feeding, positioning, bending, down loading and other processing procedures, which dramatically improves production efficiency.

●ACL bending machine + ESTUN manipulator increase efficiency, reduce rejection rate, being environmentally friendly, reduce labor intensity and save cost.

●Shanghai Xinli WF67K bending machine+ESTUN manipulator are of military quality and make high performance.

●GOLTEC is devoted to CNC punching automatic uploading and downloading equipment and warehouses. Its products win the favor of ESPEC, Zomier Aluminum, South Hotel Articles CO.,LTD., YAWEI and other companies.

Loading...

Loading...