Intellectual industry of China is facing unprecedented opportunities for development. More than half of enterprises are in the key industries which are in urgent need of automation, which become a rare business opportunity for industrial automation manufacturers. More and more industrial automation enterprises also take Chinese market as an important target. Shenzhen and the Pearl River Delta economic zone are the most important manufacturing hub of China in the industries of 3C products, automobile manufacturing, electronic and electrical, new energy, medical apparatus, electronic equipment, horologe, glasses, food and beverages, stationery, plastic, mold and hardware products, which become next big place for automation enterprises to focus on and expand. Industry of China needs a wide range of automation equipment products and a variety of mechanical transmission solutions are needed. SIMM Exhibition specially sets up Mechanical Transmission and Control Integration Application Area, exhibiting the latest technology, product and the most valuable solutions in transmission industry, to meet the needs of complex production process of manufacturing enterprises in Southern China.

Representative Exhibitors

igus, SCHNEEBERGER, BOSCH-REXROTH, R+W, NEUGART, THK, IKO, HD SYSTEMS, DURI, HIWIN, TBI, LEADER, DEX, YONG-HONG, ABBA, TPI, CSK, CPC, SUNET and so on.

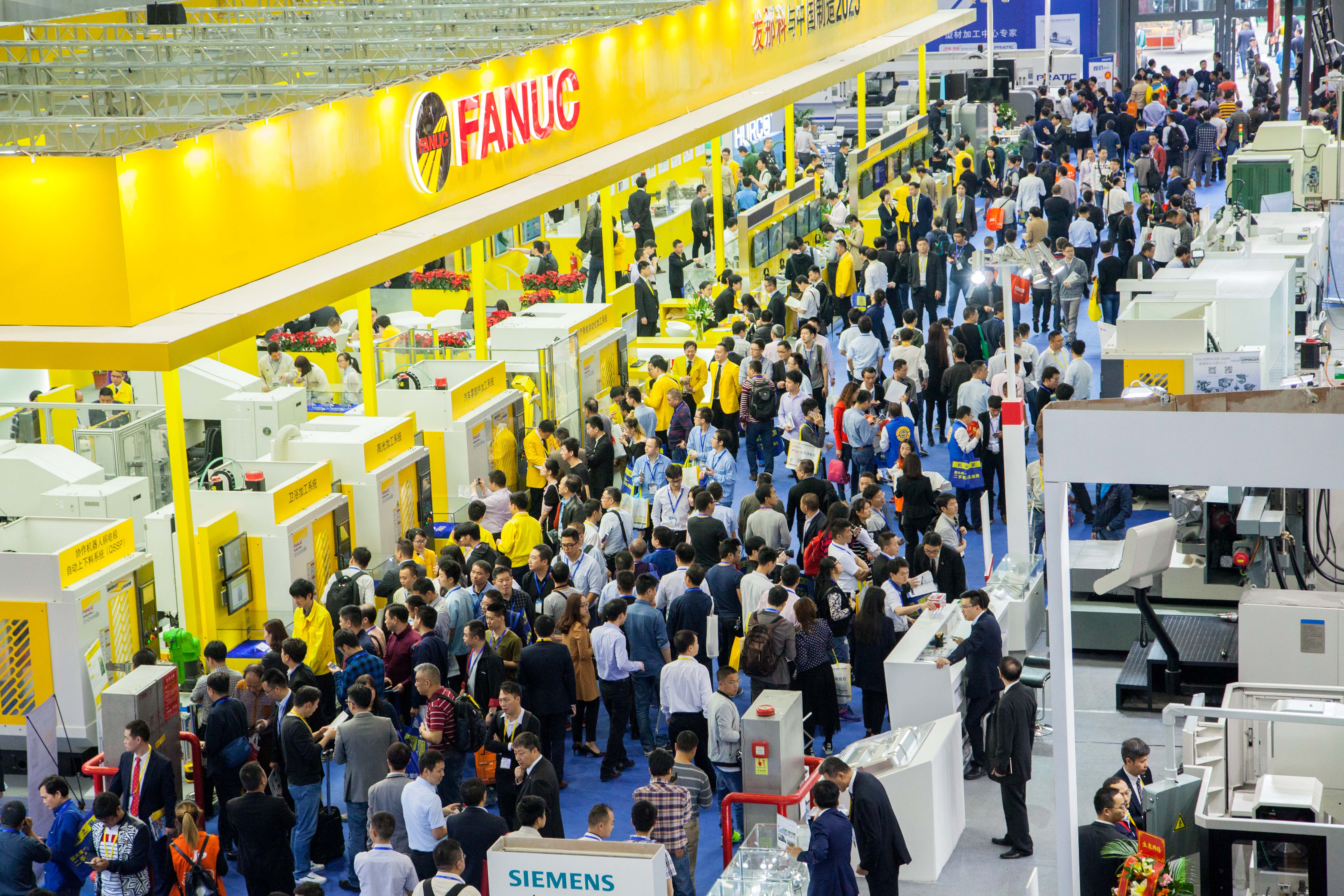

In order to meet the needs of smart manufacturing upgrade these years based in south China, we, as a professional exhibition organizer, provide SIMM platform for so many industrialists that visitors can find various automatic applications or robotics hardware here, such as intelligent production line; IIoT system; robotics workstations (welding, assembly, polishing, loading and unloading, palletizing, carrying, spraying, sorting and 3D scanning); flexible manufacturing system; machine vision system and solution; robots and parts; tooling and fixture; AGV & intelligent solution and supply chain, non-standard automatic equipment; FA plant automatic parts.

Representative Exhibitors

FANUC, YASKAWA, Kawasaki, Nachi, Universal Robots, EPSON, OTC, TOSHIBA, Rethink, A&E, HS ROBOT, GSK, ROKAE, FUJISAN, Ceway, TEDArobotics, Pioneer, OTG, CUIFENG, SONGQ and so on.

Loading...

Loading...