2020/01/15 09:00 | Pageview:2326 | From: ITES Official

Booth No.: 6-KO4

IPG Photonics Corporation is a global leader in high-power fiber lasers and amplifiers. The company was founded in 1990, and it advocated the promotion and commercialization of active fiber-based lasers in a variety of advanced fields such as materials processing, communications, medical treatment, and scientific research. The application of fiber lasers has brought revolutionary changes to the laser field. With its superior performance, reliability, and low comprehensive use costs, it has reduced costs while improving productivity for users. IPG is headquartered in Oxford, Massachusetts, USA, and has production, sales and service bases in many countries around the world. The wholly-owned subsidiary established in Beijing, China is mainly responsible for market development, application research and development, system integration, product sales, after-sales service and technical support of IPG fiber laser products in China.

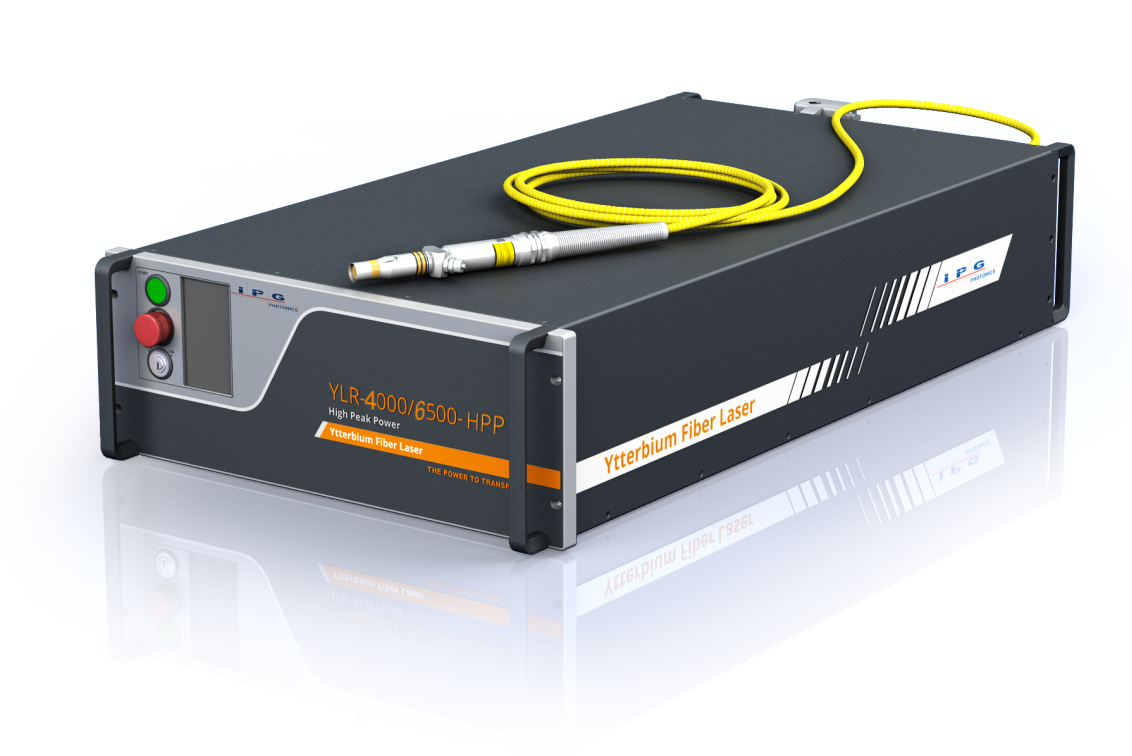

Featured product at ITES 2020

IPG Photonics introduces new High Peak Power (HPP) options on the latest YLS and YLR laser. The HPP enables users to run continuous lasers in pulsed mode, and the peak power can be doubled compared to continuous output power. This mode enhances the performance of lasers in laser cutting applications, thereby increasing perforation speed, improving perforation consistency and reducing waste. The peak power mode comprehensively improves the processing speed. Even if there are micro-features at the corners of complex parts, it can achieve higher cutting quality and reduce the overall laser power demand. The peak power boost mode supports clean and controllable penetration of thicker materials, further enhancing the drilling capabilities. For cutting applications, this means shorter lead-in lines and denser markers, reducing material waste. IPG's exclusive peak power mode can significantly improve cutting and drilling quality and increase overall yields while saving material, time and operating costs.

YLS Series High Power Erbium Doped Fiber Laser

The output of IPG’s YLS series laser is up to 120 kW and it can operate in continuous or modulation mode. There is no change in beam divergence or beam profile in YLS laser at a dynamic range from 10% to full power. High brightness allows the use of long focal length processing lenses to greatly increase the depth of field in applications such as remote welding. The YLS system is installed in a rugged and self-contained air-conditioning and sealed cabinet. It is controlled by digital I / O, analog control or IPG's own LaserNet software. You can choose to add DeviceNet, Profibus or Ethernet interface. The YLS system is equipped with the widest range of fiber core diameters, fiber lengths, and various multi-port beam switches, allowing lasers to share time or energy between workstations. IPG has developed various beam-transmitting optics in recent years, tailored specifically for use with YLS lasers in cutting and welding applications. These beam-transmitting optics include cutting heads and welding heads, 2D and 3D high-power scanning heads for remote welding, and swinging welding heads, which provide a variety of beam path options to meet different application requirements, such as bad welding parts.

Features:

-Output power is up to 20 kW at workpiece

-The beam quality is excellent. Continuous mode and modulation mode are the two beam adjustable modes that can be selected.

-Optional quasi-continuous peak power

-Maintenance-free operation

-Electro-optic conversion efficiency: 45%

-With a compact modular ‘Plug and Play’ design, it is stable and easy to install. The matching chiller is optional.

-Diode thermal redundancy

-Optional: integrated optocoupler or shutter

Applications:

-2D/3D thin & thick metal cutting -Drilling

-Stainless steel cutting -Cladding

-Processing of copper, brass, aluminum and titanium -Brazing

-Welding -Heat treatment

Loading...

Loading...