2020/05/11 09:00 | Pageview:2011 | From: medium.com & Unbox Robotics

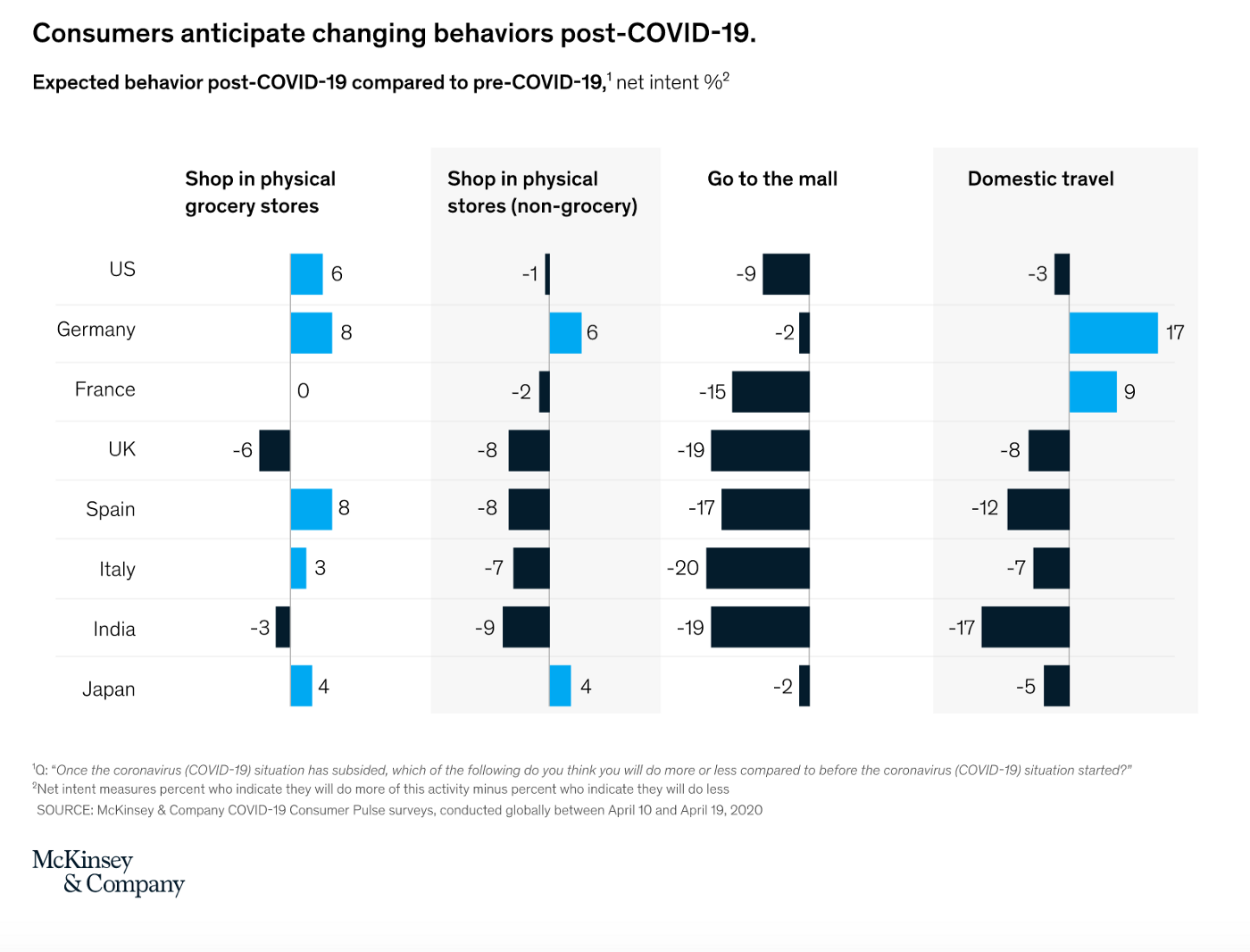

COVID-19 has left no stone unturned when it comes to disrupting businesses, and retail (both online and offline) has been far from an exception. The contagion and the recession drive the ‘New Normal’ which sees increased social distancing, micro-lockdowns, increased pay cuts or unemployment, the gig economy, and work from home. More people will prefer home delivery of food instead of going to restaurants. Work-related travel will reduce making way for remote meetings and conferences will make way for webinars. Across most of the geographies, the consumers are giving preference for online shopping.

E-Commerce surge affecting the logistics industry

Operational uncertainty has been the most significant logistical hassle with last-mile delivery bottlenecks. Although there has been a considerable increase in spending on essential products (groceries, fresh, and medicines), other sectors have witnessed significant demand shocks and cash flow turmoils due to ailing supply chains.

While the far-reaching outcomes of this global epidemic on the online retail industry are evidently positive, the short term is spelling a gloom for most e-commerce players and their logistics partners. For most sectors in retail, there is little clarity on how and when the situation will turnaround. With this uncertainty, logistics players have moved into cash conservation mode and put all their expansion plans and significant investments on hold. The focus is swiftly changing to the new demand patterns. Large e-commerce players have started augmenting their regular fulfillment centers also to serve the increased demand for groceries. Logistics partners have also used their operational capabilities to meet the changing demand patterns. The new focus is hyperlocal orders related to food, groceries, fresh, medicines, and other essential items. In the US, the logistics giant United Parcel Service Inc. saw home deliveries spiked nearly 70% by the end of March, with drivers making 15% more stops on their daily routes.

Loading packages into a truck at UPS’s Mesquite facility. PHOTO: BRANDON THIBODEAUX FOR THE WALL STREET JOURNAL

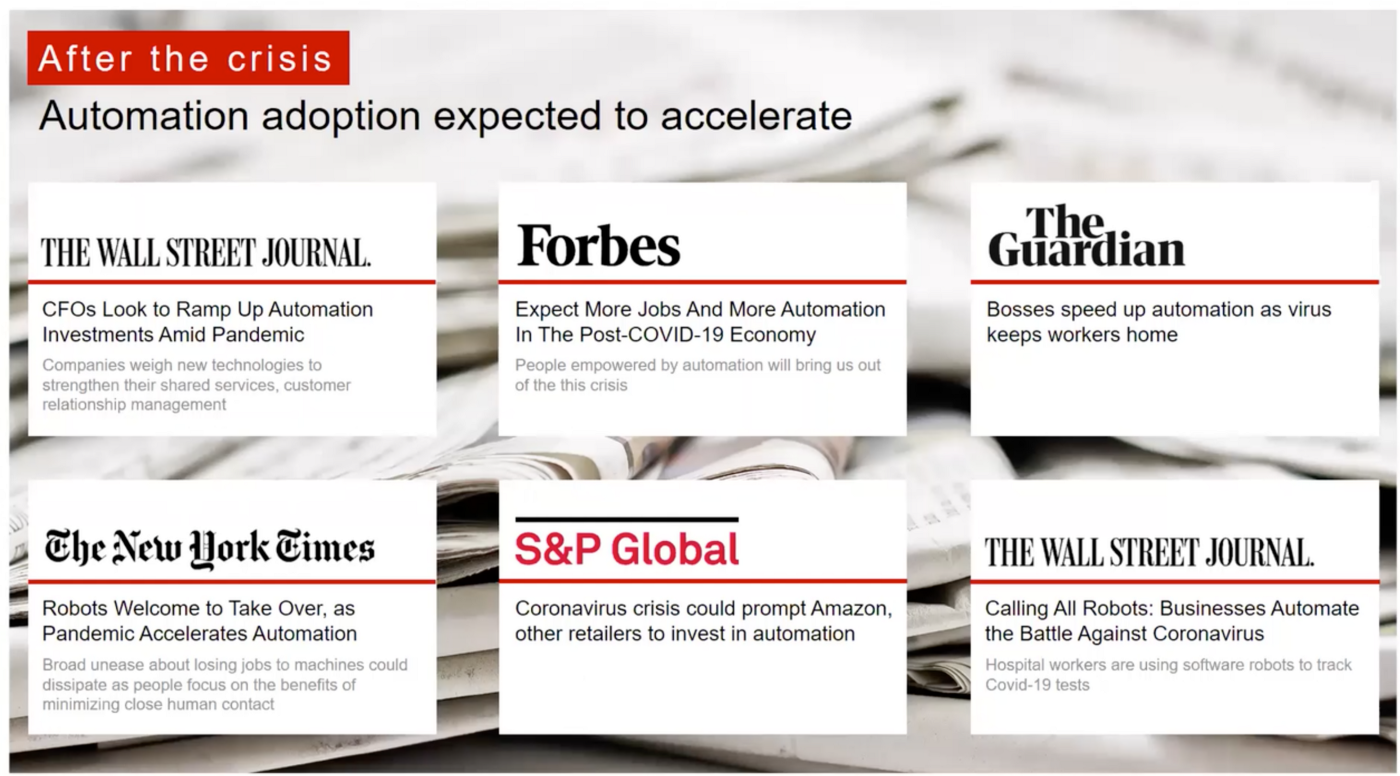

Automation is all the more necessary now

Various reasons why automation has increased the mindshare of logistics players. Some of the reasons are mentioned below.

Accelerated shift to online businesses

The current situation has encouraged a significant shift of sellers to the online space. In Asia, the retailers are expecting a “sticky” increase in online penetration of three to six percentage points as they reopen stores. In India, the Confederation of All India Traders (CAIT) is soon launching an e-commerce platform — bharatemarket.in — for retail traders across the country. MyGate, an app that services 7,000 housing societies, is enabling grocery order in over 1,100 communities in metros. Consumer goods companies facing broken supply-chain networks are forging new linkages with food aggregators, hyperlocal apps, and courier firms, reshaping the old model of depending solely on wholesalers, distributors, and retail stores to reach customers. Tele-services and apps to help retailers place orders are also being rolled out during the lockdown to limit the spread of the novel coronavirus. The pandemic is expected to accelerate the demand growth for online retail putting huge pressure on the e-commerce and express logistics supply chains. It has become essential for companies to build agility in their supply chain and adjust the fulfillment and distribution center operations.

Costco cited stay-at-home orders, social-distancing restrictions, and some mandatory closures for the lower traffic and sales. Source: WSJ, PHOTO: ROD LAMKEY/CNP/ZUMA PRESS

Ability to deal with manpower shocks

The logistics industry is facing huge supply shocks due to the lockdown. Mass migration of the workers has left them with little access to affordable labor in the near term. At those places where labor is mostly local, social distancing norms have resulted in warehouses operating with less than 50% staff. Even as operations start in the near term, if a single operator is infected, the entire facility may need to be quarantined and disinfected. One cannot ignore the fear it will instill in the remaining employees. With automation technology providers building efficient and flexible solutions for almost every critical process in the supply chain, automation will soon become commonplace in the logistics sector.

Reduce the handling of shipments

We are rapidly moving towards a world that is ‘touchless’. In India, most hyperlocal players like Swiggy, Zomato, and Dominos are reassuring their customers and delivery executives by introducing touchless deliveries. In e-commerce, a typical shipment may be touched 6–8 times before reaching the end consumer, increasing the risk of contamination. With automated material handling processes, logistics players can reduce the number of people touching the shipment in its course and get them down to just 2 or 3, depending on the scope of automation.

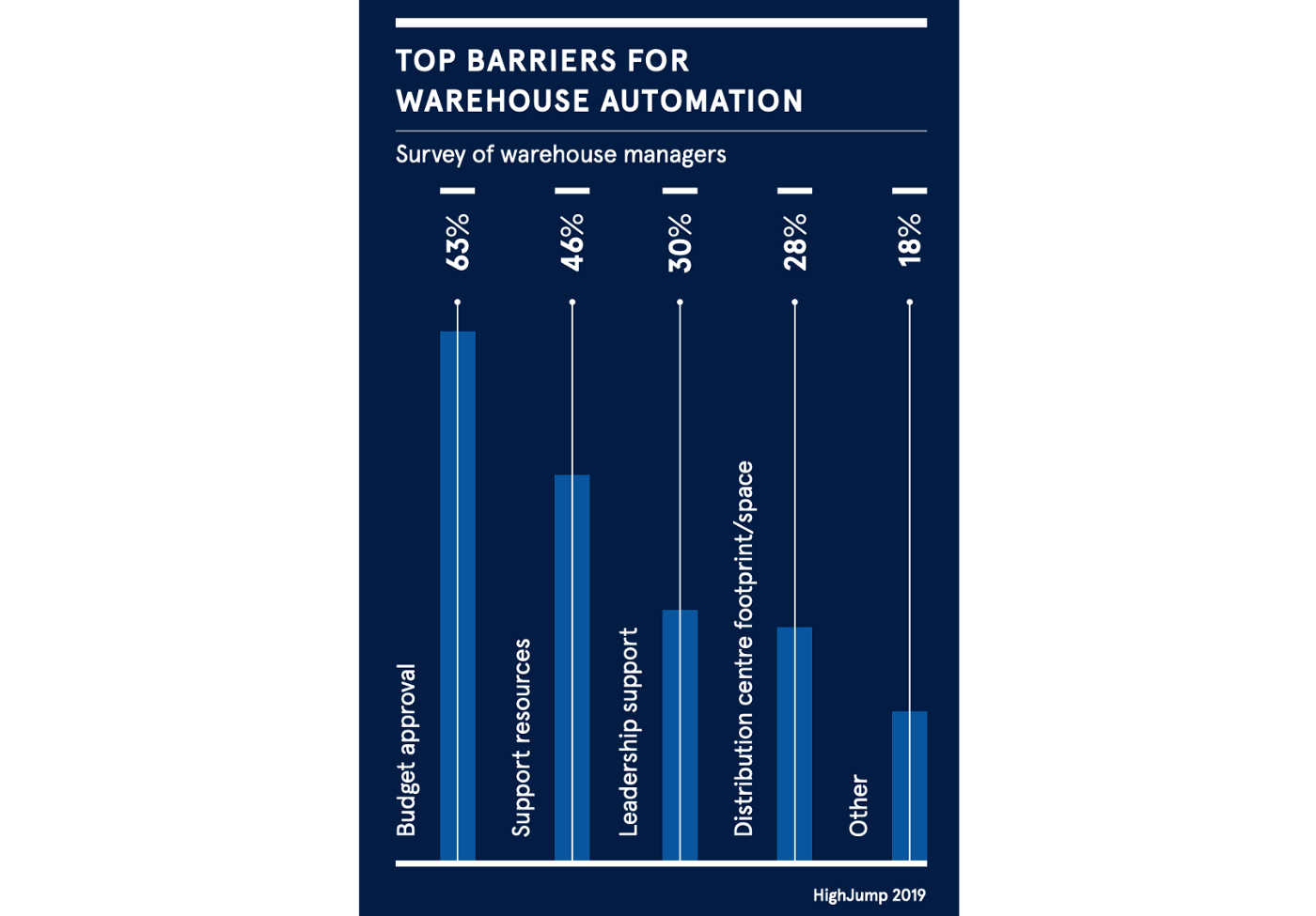

Characteristics of Automation required

With COVID-19 forcing organizations to constantly explore braver workflows, companies are in dire need of automation solutions. Traditionally, there have been barriers to automation right from capital requirements to space required, etc. In the warehousing facilities, the companies need to look for scalable automation solutions that can adapt to their business plans without costing a lot of money and space.

From a WSJ article, “For an older hub, automating is like heart surgery,” says Ted Dengel, FedEx Ground’s managing director of operations technology.

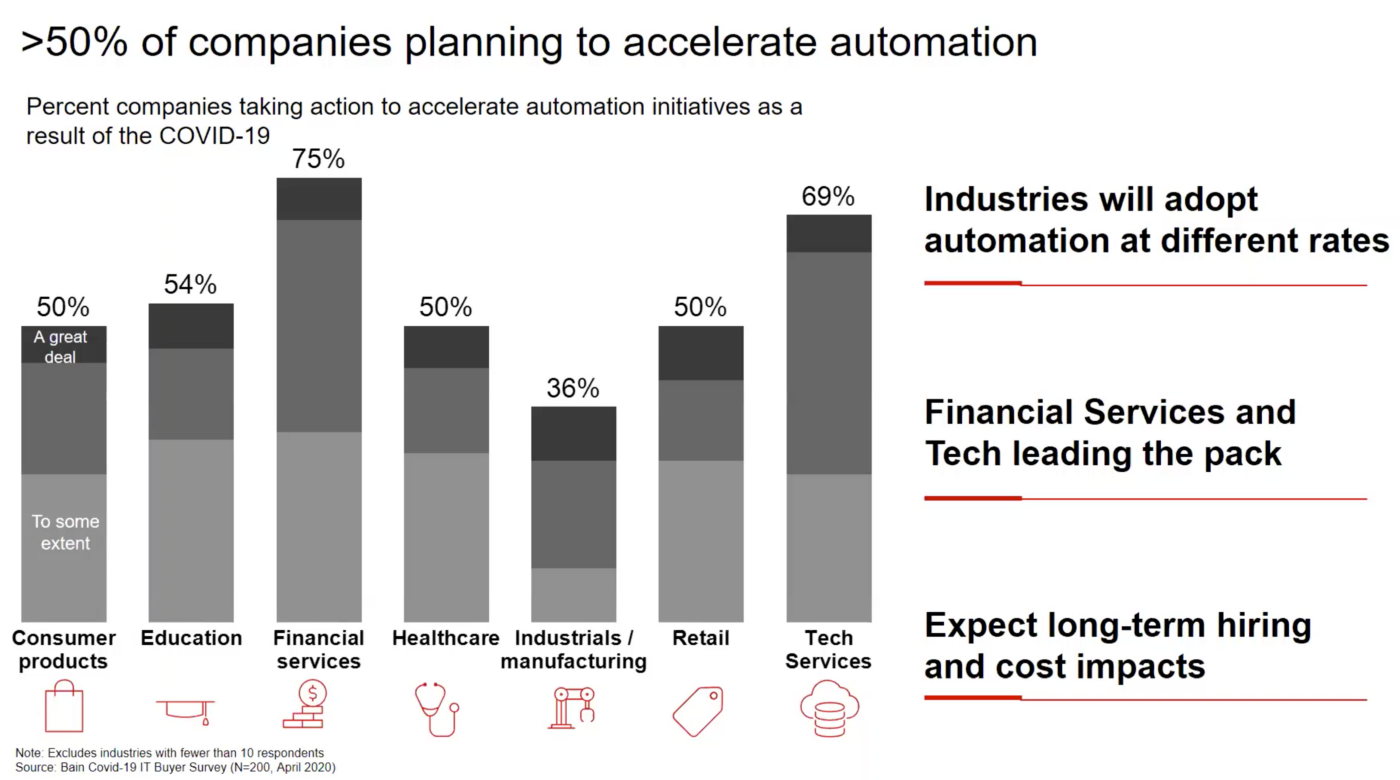

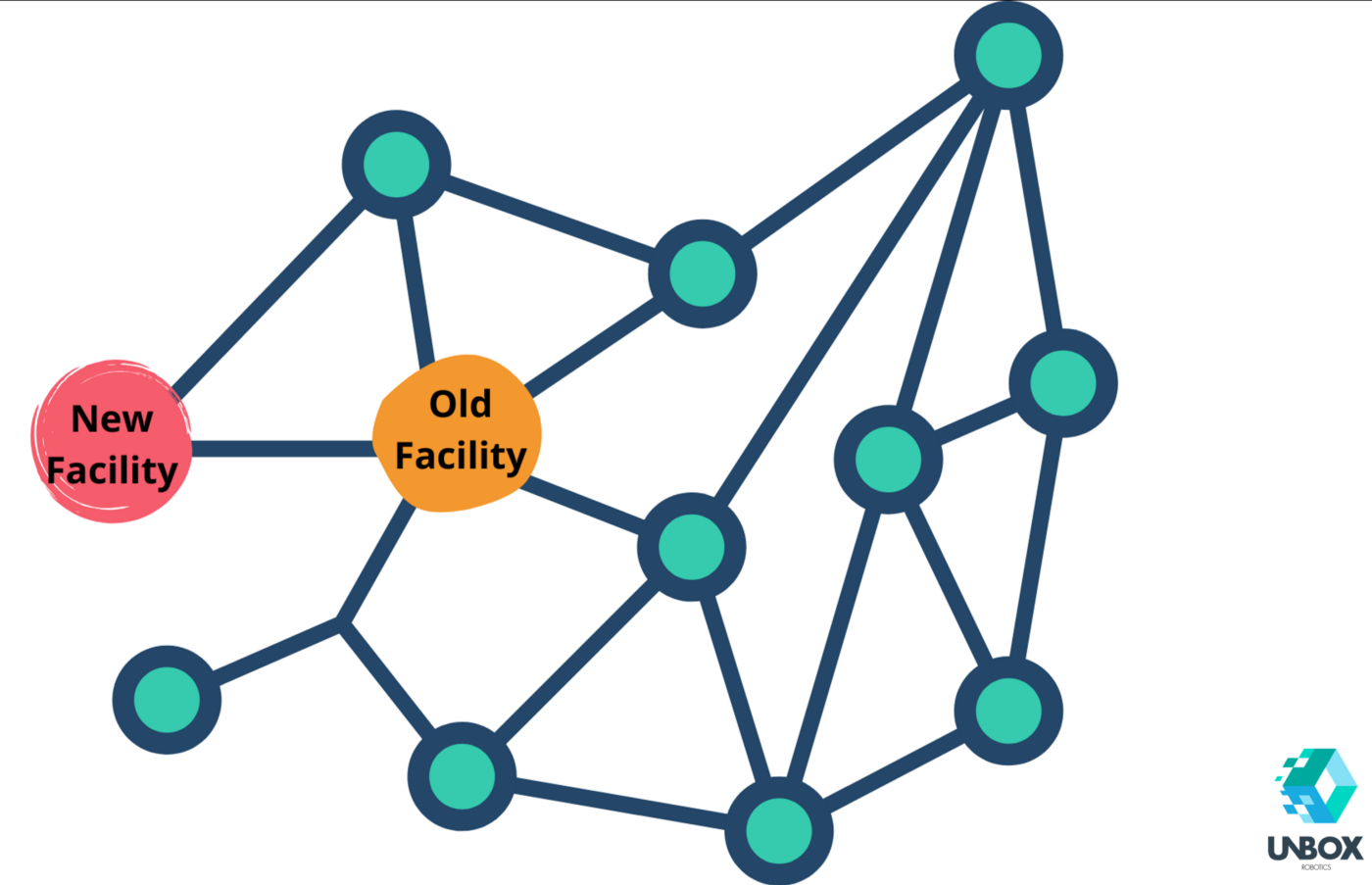

The ability to automate old as well as new facilities by using plug & play automation solutions is the key going forward. We are already looking at a positive trend in the adoption of automation across industries.

We identified the following traits of automation that are most suited for the logistics industry going forward.

A. Scalability

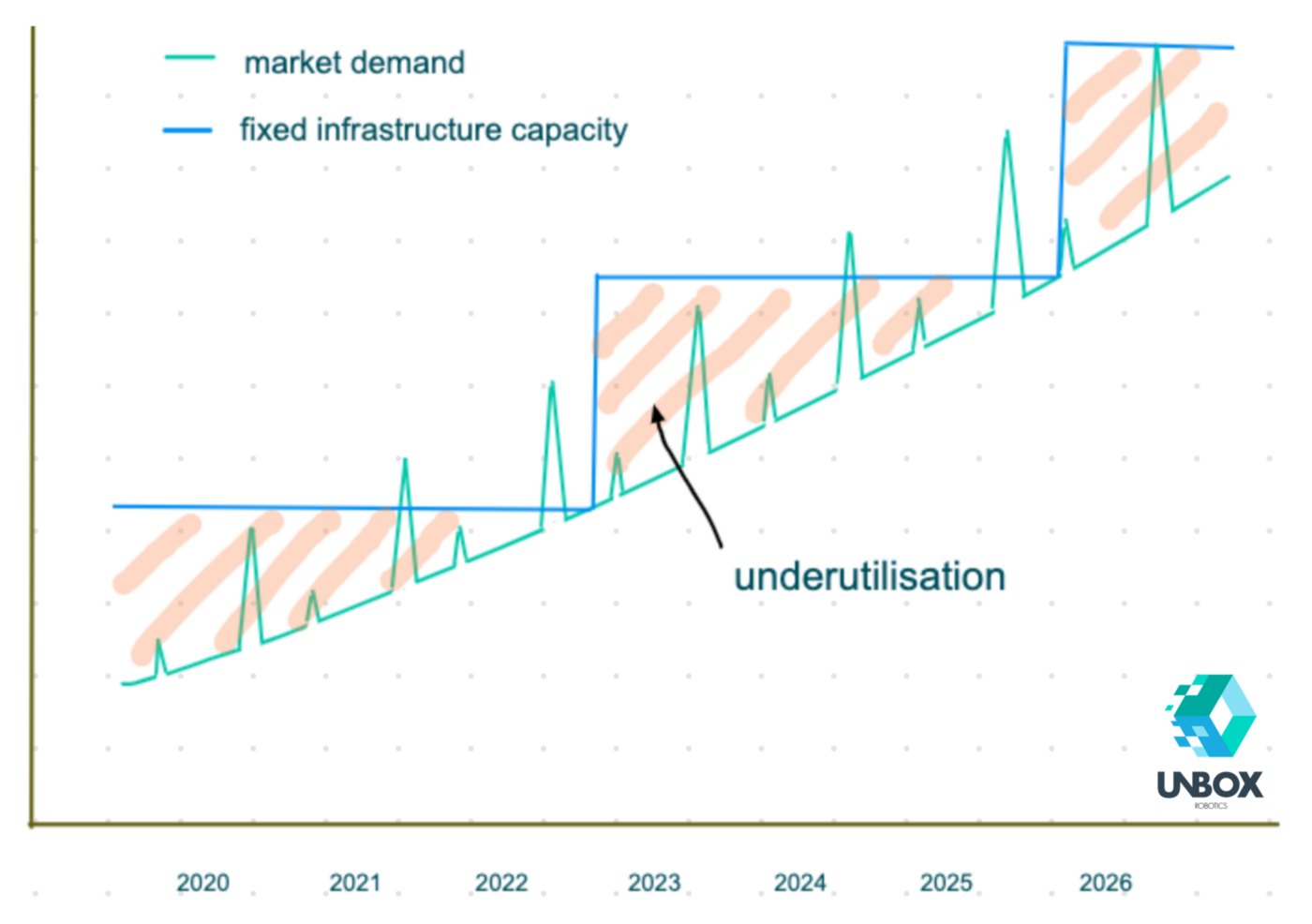

In these uncertain times, predicting demand, or its growth for a particular region is a major challenge for logistics players. Markets which normally saw demand growth of 30–40% YoY, will now need to plan for a much higher rate of growth of online shopping. Traditionally, facility automation has been designed with respect to capacity planning for 3–5 years.

This leads to massive underutilization of space and capital, which are in short supply in the current scenario. Making solutions easily scalable allows space and capital investment to follow the growth curve of demand.

B. Flexibility

Change is constant. This mantra holds true even for the supply chain network design of rapidly growing logistics markets. As companies grow, they expand their geographical reach, product categories, and supplier base among other things. Each of these has a significant impact on the size and location of their warehouses and distribution centers. Temporary capacity building for seasonality and peak sale events like Prime Day, Single’s Day, or Big Billion Day need to be planned for. Solutions that are easy to move, install, and integrate into the warehouse systems allow frequent changes in network decisions with minimal disturbance of the supply chain.

The flexible automation solution can move across the facilities very easily from old to newly introduced facilities in the supply chain network. © Unbox Robotics

As such, automation solution providers should build modules that are light on infrastructure and versatile to suit different warehouse conditions. Setting up and removing the solution from a facility can be made quick and easy enhancing the agility of the supply chain.

C. Affordability

The pandemic has taken a major toll on the economy, converting an already existing recession into a depression, with significant and potentially long term impact on major sections of the market. In these times, cash conservation is the mantra for individual households as well as upcoming businesses. Express logistics players are no exception to this behavior, and few players we’ve spoken to have pushed ahead of their heavy capital expenditures indefinitely. Automation solutions that are modular and scalable, can also be extended on a pay-per-use basis, thus making them affordable for even the smaller or upcoming players in the logistics industry.

Source: Bain & Co.’s webinar “Accelerating Automation amid a Pandemic: Implications for PE Investors and Portfolio Companies”

Loading...

Loading...