2020/05/20 09:00 | Pageview:1899 | From: ITES Official

There is no doubt that in the second half of 2019, TWS headphone is the hottest product in the consumer electronics market.

All related manufactures have entered the market. TWS concept stocks with the label of “Best Earnings” are the most powerful proof of its popularity. Among them, Edifier has created the miracle of rising 294.16% in 60 days, 400% increase in half a year. The core concept stocks of wireless headphone sector, such as Shenzhen Rapoo, Yingtong Telecommunication, Shandong Gettop, Cosonic Intelligent Technologies also exploded and rose one after another.

But behind the hot market, some difficulties in 3C manufacturing threaten the further development of TWS industry.

The TWS Manufacturing Needs to be Improved

On average, 36 assembly + testing workers in each production line;

About 500 assembly + testing workers in one factory;

Production capacity: 10 hours/ 2,400 headphones;

More than 200 categories of products...

This is the production status of a Bluetooth headset factory visited by ITES recently. Due to the wide range of products and the small precision parts, the assembly process requires a lot of manpower. "Our company hopes to realize automatic production gradually, but it is impossible to realize the full section automation due to the product process and other reasons, only limited single station automation can be achieved. Besides, as there are so many categories, once the product changed, the automatic devices will not be suitable anymore." The owner said to ITES.

Recently ITES visited a leading Bluetooth headphone company and found a huge automation market. After on-site filed study and introduction by the engineering director, ITES found that in the production process of TWS headphones, the stations that most need to be automated are concentrated in the three steps: assembly, packaging, and testing. There are 36 workers responsible for assembly and testing per production line!

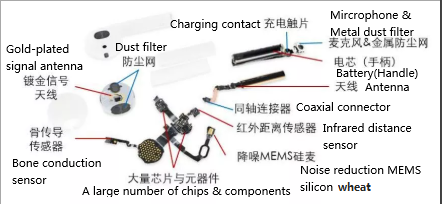

We had an intuitive understanding of the complex structure of TWS headphones on-site. The physical structure of different parts of TWS headphones is different, among which the charging box is mainly composed of IC chip, battery, and charging module, while the two independent headphones are relatively complex, consisting of a battery, earphone unit, feedback microphone, and various sensors. Due to the small size of the headset, it requires high technology of battery and chip, which also increases the difficulty of automatic assembly and testing.

TWS Headphone Take the Lead

Headphones are divided as wired, wireless & Bluetooth, and true wireless stereo (TWS). With the release of the first generation of AirPods by Apple in 2016, the era of TWS headphones began. After a short period of market development, mobile phone manufacturers, traditional audio manufacturers, and other manufacturers continue to enter the market, and the TWS headset market has entered a stage of contention.

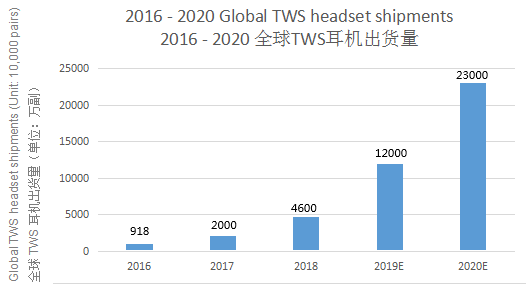

According to the data, the global TWS headset shipments were only 9.18 million pairs in 2016. In 2018, Huawei, Xiaomi, and other Chinese enterprises joined the market one after another, TWS headset sales reached 46 million pairs, with an annual compound growth rate of 124%. It was estimated that 120 million TWS headphones shipped globally in 2019. After using the headphones for 2 to 3 years, early users are now facing the obvious decay of battery life and incentive by new functions, which is expected to lead a new wave of headphones replacement. It is estimated that the TWS headset shipments will jump to 230 million pairs in 2020, with an annual growth rate of 91.6%. The widespread adoption of TWS headphones is just around the corner!

Breaking Through the Difficulties

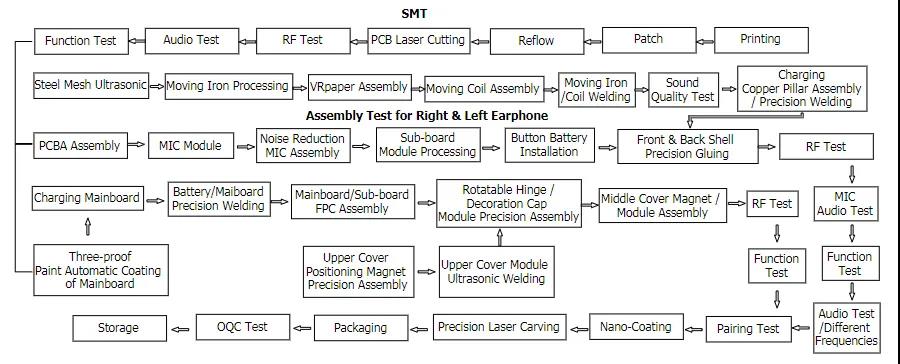

Facing to the explosive growth, automation companies need to break through difficulties to gain the profit. The manufacturing process of TWS headphones includes a large amount of precision assembly and testing. Taking a brand as an example, their headphone involved nearly 30 manufacturing processes and 12 testing processes, which puts higher requirements on ODM / OEM manufacturers.

TWS headphone manufacturing process

It can learn from this business visit that TWS headphones will become smaller and smaller for more convenience, good appearance, and portable, but more functions. Through interviews and investigations, we learned that the TWS headphone manufacturing process has the following difficulties:

Diverse Categories

The problem of flexibility has always been the key difficulty in automation. Nowadays, consumer electronics products are updated frequently, and the requirements for flexible automation are becoming higher and higher. In the investigation, there is more than one company that needs to produce as many as 200 types of products. Therefore, the automation enterprises that want to make some achievements in the 3C industry should first conduct in-depth research on the issue of flexibility.

Process Requirements

For example, glue is required for the bonding of TWS headphones. The fastest setting glue takes 8 minutes to bond, which greatly hinders the processing;

In addition, the left and right earphones are similar in appearance. To use automatically distinguish is difficult to put them into the charging box, while to use the vibration plate is easy to scrape the appearance of the cavity.

For another example, TWS headphones are small in size but it needs to be "insert" a lot of chips and sensors into a narrow cavity, which has high requirements for precision, strength, and stability of automatic operation.

Airpods headphones main structure

From the survey done by ITES for many years, there is still a lot of demand for automation in all sectors of the consumer electronics manufacturing industry. Especially under the popularity of smart wearable and smart homes, the complexity and integration of products continue to improve, and traditional manual assembly, testing, and packaging have been unable to meet the industry needs. However, it is also difficult to achieve the automatic upgrade of these sectors at one time. But it is a certainty that the first batch of automation companies who overcome the challenges will grasp the future development opportunities.

For more information about 3C industry automation applications, robots, and robot-related content, please visit Shenzhen International Industrial Manufacturing Technology Exhibition (ITES) & the 21st Shenzhen International Machinery Manufacturing Industry Exhibition(SIMM). Looking forward to meeting you on Sept. 1st - 4th at Shenzhen World Exhibition & Convention Center (New venue).

Exhibition Contact:

Ms. Talina Zeng

Tel:+86-755-23940012

E-mail: info@simmtime.com

Loading...

Loading...