2020/08/03 09:08 | Pageview:1561 | From: metrology.news

Hexagon’s Manufacturing Intelligence division has launched a new modular software suite, HxGN NC Measure, making it simpler and faster for manufacturers to inspect diverse parts directly on the machine tool.

Designed for ease-of-use, the modular HxGN NC Measure suite allows manufacturers to quickly and accurately undertake either routine or complex inspections directly on the machine tool, with users able to capture, report and use data in the way that best suits their individual needs.

The HxGN NC Measure | Core software package combines a deep understanding of production processes with a highly intuitive interface to make it easy for users to set up and inspect workpieces and create reports that inform rapid decision making.

Manuel Müller, Product Marketing Manager at Hexagon, says: “Manufacturers are benefiting from advances in machine tool inspection technology to inspect a growing number of parts directly on the machine tool. Hexagon’s expertise in machine tool inspection and metrology software means we’ve been able to lead the way in simplifying machine tool measurement for our customers, including for complex laser-scanning applications.”

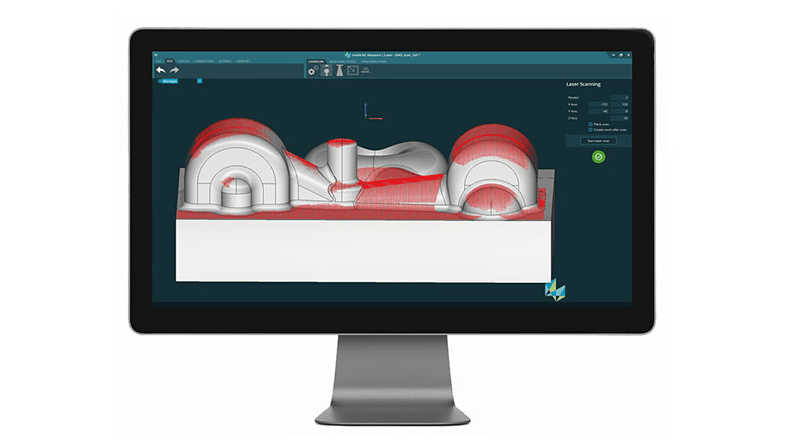

Additional modules enable operators to perform more tailored or complex inspection tasks and include a ground-breaking module for laser-scanning which makes it possible to accurately capture point clouds for the entire surface of a clamped part. Laser scanning on machine tools offers many advantages over tactile measurement or the use of external inspection systems. Hexagon laser scanners for machine tools are able to capture thousands of measurement points per second, so that a part’s surface can be visualised, assessed for tolerance or re-aligned on the basis of multiple part areas and many data points.

With HxGN NC Measure | Laser, using laser scanning to capture complete point clouds on machine tools has never been easier. HxGN NC Measure | Laser enables users to rapidly generate measurement data for the complete surface of a part and gain insight into its quality and exact position. Results can be viewed as a colour map super-imposed on the digital CAD model of the part, while it is still clamped on the machine tool. The software also makes it simple to create measurement reports for further analysis or for use in later production steps.

Other modules include HxGN NC Measure | Report for saving and exporting data in multiple formats and protocols. HxGN NC Measure | Best-Fit Pro meanwhile saves time by automating part adjustment to ensure the best fit for the part on the machine tool.

HxGN NC Measure is initially available for Siemens, Heidenhain, Fanuc and Röders-controls. Designed to be future-proofed, it enables machine tool companies to keep up-to-date with the latest innovations without having to acquire new software skills.

Loading...

Loading...