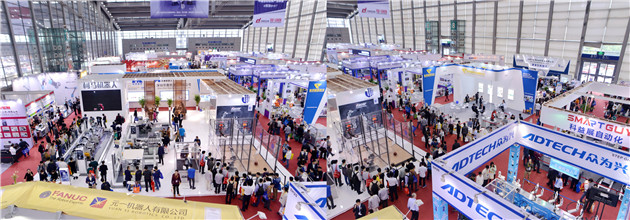

In order to meet diversified demands of intelligent modification, push forward the process of automation and intelligence of modern manufacturing in China and accelerate the implementation of automation upgrading project, SIMM broke through in the exhibition mode in the area. Based on the demands of upgrading transformation project of factories, SIMM makes the implementation solutions of smart factory as the aim to realize the information sharing and business matching between exhibitors and visitors in the exhibition. This area exhibited robots of world-renowned brands, applications of robot, non-standard automatic equipment, applications of FA automation parts. After years of development, it has now become one of the most specialized display area in industrial automation and robot industry in South China.

Features and Trends of the Display:

The current smart factory is not just about automation. It is based on the control of Internet of things through the real-time manufacturing monitoring process to ensure the normal functioning of work flow. To keep up with Industry 4.0 and meet diversified demands of market, the robot and applications hall is working on building up a first-class and smart display platform. It used the form of dynamic demonstration of objects for the first time to exhibit the automatic production line to visitors in manufacturing industry to provide the prototype for automatic and digital workshop. In addition, customized business plans of smart factory are introduced to provide users with comprehensive and systematic smart factory solutions.

Representative Exhibitors:

COMAU, H.S Robot, Universal Robots, kawasaki

● COMAU from Italy, the world leading manufacturing company of flexible automation system, took part in the exhibition with its diversified products. The company exhibited the assembly production line of COMAU robots parts, realizing multistage assembly and production of electronic components, which became the representing case of newly automatic factory.

● H.S Robot presented with the exhibit "Smart Factory - Made in China 2025 Model Workshop". The model workshop is mainly composed of high-speed drilling center machine, industrial robot and jig, digitized and automatic assembly line based on RFID, online detection system, smart logistics system and smart security and protection system.

● The flexible assembly robot solutions brought by Universal Robots provided solutions to flexibility needs of electronic manufacturing companies, which can successfully realize flexible assembly of CPU, DIMM, memory banks and other sophisticated parts by touching and adjusting to precisely position.

● Kawasaki cooperated with Dongguan Cuifeng Machinery to exhibit "DuAro", the human-computer collaborated and double-wrist positioning robot made by Kawasaki. "DuAro" is a new solution in introducing robots into small companies to solve the problem of short life cycle of products, low-end process of assembly and inspection procedure of electronic industry and slow introducing.

Features and Trends of the Display :

Digitized smart factory may seem inaccessible to many small businesses, but the smart transformation and upgrading of small manufacturing enterprises has a large market. In order to provide more solutions to smart transformation to enterprises in every part of the manufacturing industry chain, SIMM together with a number of qualified suppliers in smart manufacturing from domestic and overseas displayed diversified, small-batch and customized solutions in smart manufacturing to visitors. Both of the design and functionality conforms to properties of production and conditions of enterprises. The functionality can be improved according to requirements and is more flexible in adjusting, which is convenient for manufacturing enterprises to operate and produce.

Representative Exhibitors:

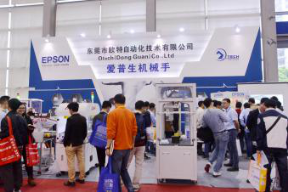

Epson, SMARTGUY, Pengzhou Intelligent Technology Company, HITOP, GSK

● Epson industrial robot brought several solutions in 3C manufacturing industry, which showed its power of technology in convenience and efficiency: 1. robot burring solutions; 2. EPSON RS3 automatic calibrated visual system solutions; 3. PCB special-shaped inserting machine solutions; 4.FPC smart laminating solutions; 5. force sensor assembly solutions; 6. motor assembly solutions

● SMARTGUY exhibited automatic equipment of 3C product processing; assembling and testing equipment of 3C product, SMT jig; smart logistic equipment

● Exhibits of Pengzhou Smart Technology: 1. EPSON G6 cleaning robot and smart visual guidance assembling show; 2. COMAU Racer7 robot, 1 versus N tool machine feeding system; 3. ABB IRB0 mobile shell polishing work station robot

● The practitioner of industrial automation HITOP took part in SIMM exhibition with various self-developed innovative technology product and attracted lots of visitors.

● GSK exhibited four RSP600A15 horizon robot assemble lines controlled by the bus network: adsorp, dig pits, gluing, soldering; Display of two robots cooperated to assemble the LCD; automatic polishing robot based on constant pressure controlled by the magnetic technology.

Features and Trends of the Display:

With the concept of Industry 4.0 flocking from Germany to the globe, more and more Chinese manufacturers are involved in the industrial changes featuring with digitization. At present, the uniqueness and complexity of domestic automation program lead to the problem of shortage of high-quality resources. SIMM makes use of exhibitors and visitors resources to pick up hundreds of excellent equipment and technology suppliers to create a platform of project matching and communication for manufacturing enterprises to make transformation in automation production. In SIMM, diversified and professional conferences from project analysis to application and practice are organized to meet various demands of exhibitors, buyers and professional visitors.

Representative Exhibitors:

Successful display cases in SIMM are as follows: the high surface quality polishing of fused silica glass project of Mindray; medial silicone product demould automation of Philips Respironics, medial silicone product automatic assembly, automatic synthesis graphite flake program of Shenzhen Runxingtai Co.,Ltd., silk-screen alternative project of Guangdong Xinbao Electrical Appliances Holdings Co., LTD, AGV automatic transportation project, automatic locking screw project, automatic packaging, automatic flange welding, automatic assembly and tightness test of bread barrel, automatic assembly of the oven glass door, automatic assembly of the oven control panel, automatic feeding and assembly toaster liner equipment, automatic assembly one-way valve equipment, automatic testing of eggbeater withstand voltage power, automatic plastic uptaking sealing and stacking equipment project.

Loading...

Loading...